Our Solutions

Areas for Solutions

Every operation is different — but the challenges tend to fall into a few broad categories.

Rather than selling point solutions or pre-packaged software, NexGen Insight works across these core areas to help teams gain clarity, reduce friction, and make better decisions faster.

Our Work Typically Spans One or More of These Areas

Demand Forecasting & Production Planning

Aligning demand signals with real production capacity to reduce surprises and improve service levels.

Inventory & Raw Material Optimization

Balancing availability, working capital, and risk across raw materials, WIP, and finished goods.

Sales Visibility & Revenue Operations

Creating alignment between sales activity, demand signals, and operational reality — so revenue forecasts are credible, promotions are intentional, and operations aren't blindsided by what was 'just sold.'

Quality Control & Compliance

Monitoring quality metrics, traceability, and compliance readiness without adding manual overhead.

Predictive Maintenance for Equipment

Anticipating downtime before it impacts production and aligning maintenance with operational plans.

Labor Optimization & Workforce Efficiency

Improving throughput and cost control by aligning staffing with demand and production reality.

Order Processing & Customer Service Automation

Reducing friction and exceptions across order intake, fulfillment, and customer communication.

Supply Chain & Supplier Management

Identifying supplier risk early and improving resilience across inbound materials and packaging.

Pricing, Promotions & Margin Optimization

Exposing SKU-level margin drivers and detecting cost drift before profitability erodes.

Process Automation (Cross-Functional)

Connecting systems and teams so issues escalate early — and decisions don't stall in inboxes.

From Strategy to Execution

While the solution areas above describe where we work, the real value comes from how insight is delivered day-to-day.

Below are two illustrative examples of what clients typically see early in an engagement: a unified operational dashboard and an automated decision workflow.

Example

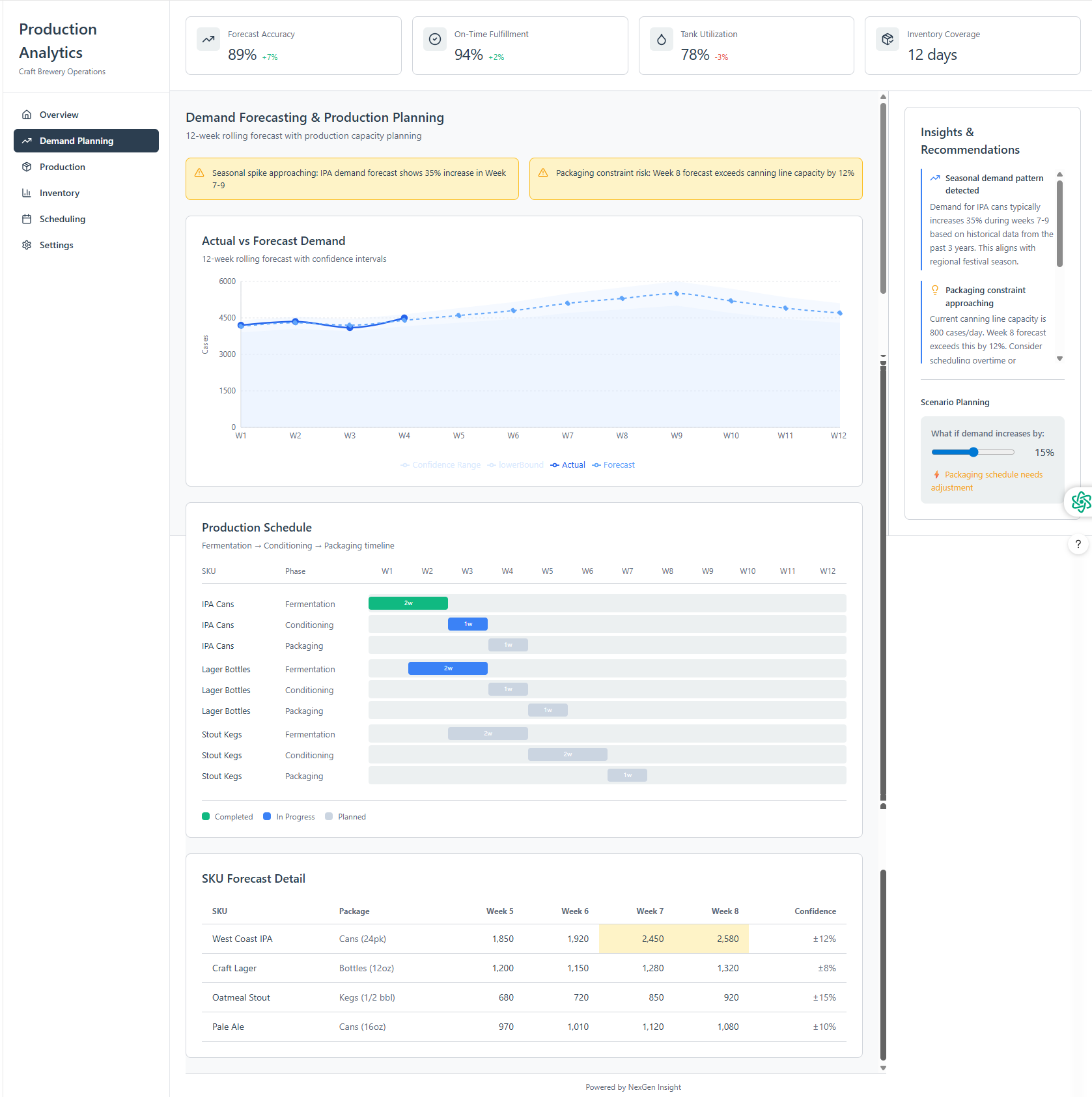

Demand Forecasting & Production Planning Dashboard

This dashboard brings together demand signals, production schedules, inventory coverage, and capacity constraints into a single operational view.

Instead of static reports, teams gain:

- Forward-looking visibility into demand spikes and risk weeks

- Early warnings when capacity or packaging becomes constrained

- A shared source of truth across planning, operations, and leadership

Dashboards like this often form the foundation — creating clarity before more advanced analytics and automation are layered in.

Example

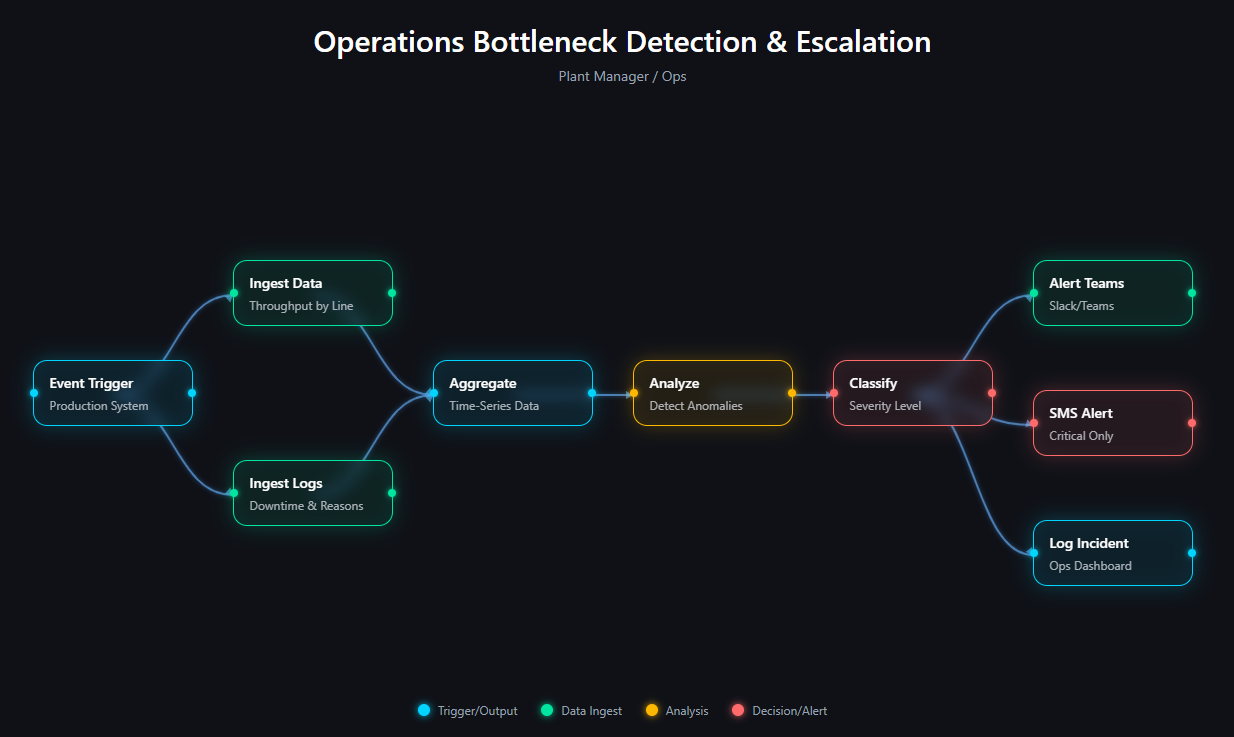

Automated Bottleneck Detection & Escalation

Operational issues rarely fail all at once. They surface as subtle signals — throughput drifting on a line, recurring micro-stoppages, or unexplained downtime that compounds over a shift.

This workflow continuously ingests production throughput and downtime data, aggregates it as time-series signals, and analyzes patterns to detect emerging anomalies.

When a potential bottleneck is identified, it is automatically classified by severity and routed accordingly:

- Low-severity issues are logged for visibility and trend analysis

- Higher-severity events trigger real-time alerts to operations teams

- Critical incidents escalate immediately via SMS to ensure rapid response

Instead of relying on manual monitoring or after-the-fact reports, teams receive early, contextual alerts — allowing them to intervene before bottlenecks cascade into missed production targets or late orders.

Designed to Fit Your Operation

These examples are not templates or off-the-shelf products. They illustrate how NexGen Insight helps organizations move from fragmented data to shared visibility — and from visibility to action.

We start broad, focus where it matters most, and deliver value incrementally.

We are not a vendor. We are an invested partner in your success.